- 18

- Jan

The automatic meat skewering machine is a new type of automatic meat skewering equipment

Atomatik meat skewering machine is a new type of automatic meat skewering equipment

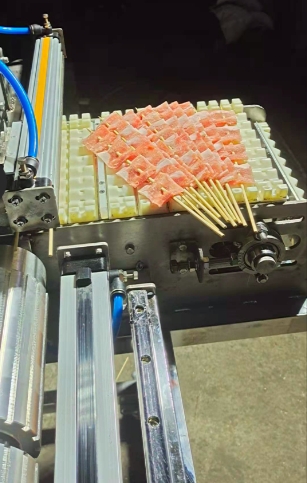

The automatic skewering machine is a new type of automatic skewering equipment. It has the characteristics of reasonable design and structure, high efficiency, easy operation, stable performance, energy saving and environmental protection. It is an ideal machine to replace manual meat skewering. The stringing machine adopts advanced single-chip technology, controls the proximity sensor, combines pneumatic and electric, and realizes active sign-up and active meat-piercing.

The automatic stringing machine is made of stainless steel and food-grade PE material, which conforms to the international food hygiene requirements. The desktop control is convenient to move, occupies a small area, and the operation is stable; the installation is accurate and reasonable, protection-free, and has a long service life; Mobile PE meat skewer mold plate, easy to clean; active meat cutting, active meat delivery, active skewering, the whole process is fully automatic operation, no need for labor, can wear beef and mutton, squid, chicken skin, meat tendons, meatballs, shrimp balls, etc. Various meat skewers and vegetable leaves can also be worn. The meat skewers are uniform in size, clean and hygienic, without rubbing, and have a good taste. You can add fat to the meat skewers in any direction, and the length of the meat skewers can be adjusted arbitrarily within the required range. Features of string threading machine: This machine is equipped with two upper and lower active tag presses on the original model, so that all types of tags used can be positioned in four directions during the threading process, and will not bow upward to present the phenomenon of broken and flying tags. .

Under the premise of increasing the output, the safety of use is further improved. The main body is made of food-grade stainless steel, and the composite plastic templates all meet the national food-grade requirements. The stringing machine has been established for many years, and has always been committed to research and processing in this area, and the selected materials are also of high quality