- 28

- Dec

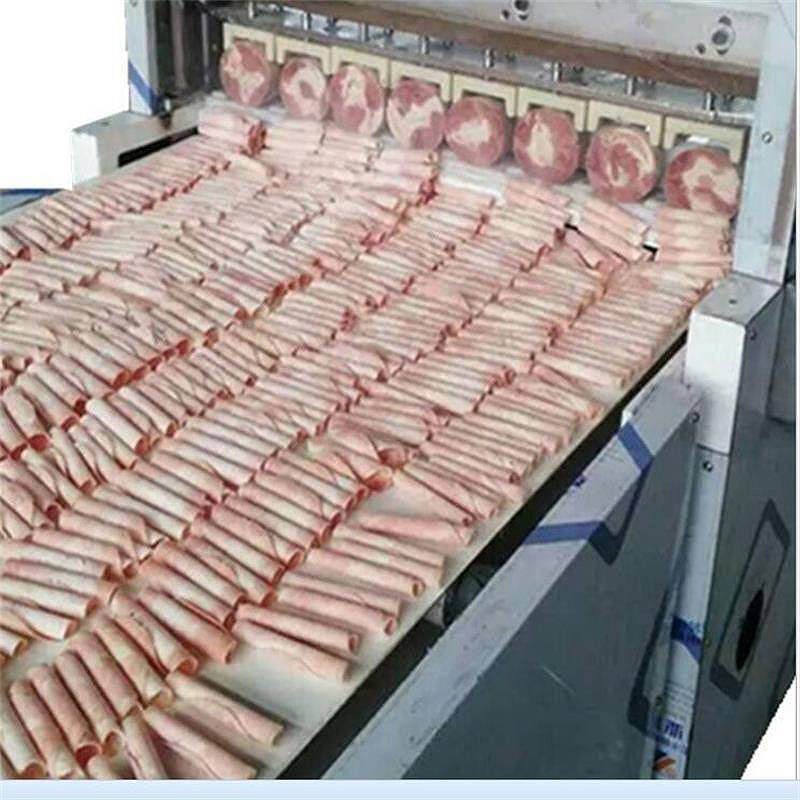

The operation process of beef and mutton slicer

The operation process of nöt- och fårköttsskärare

1. Insert a round pin into the retaining ring hole at the right end of the spindle to prevent the spindle from rotating, and then tighten the ring knife on the left spindle. Two single-edged round knives are installed on the right end of the main shaft, and a fixed washer is installed between the two blades to tighten the nut.

2. Adjust the limit screw behind the feed carriage at the left end so that the feed stroke exceeds the ring knife edge to ensure that the sample rubber is cut through.

3. Start the beef and mutton slicer and turn on the coolant knob at the left end of the water tank.

4. Stick the sample rubber material vertically and flatly on the platform.

5. Push the handle to feed the feed carriage and spin the cylinder.

6. Return to the feeding carriage, and the movable connecting rod will drive the ejector rod to eject the cylindrical sample from the ring knife.

7. After cutting several test pieces, adjust the limit screw behind the feed carriage at the right end to evenly make the two single-edged round blades collide with the sample holder. Lift the upper mold of the sample holder on the right side, insert the cylindrical test piece into the holder hole of the beef and mutton slicer, close the upper mold, turn on the coolant knob, and push the handle.

8. The connecting fulcrum of the ejector rod and the pull rod is divided into front and rear two types, and the front and back sides can be used arbitrarily according to the needs of the operator.