- 16

- Dec

Eight rolls CNC lamb slicer

Eight roll CNC slicer

The 8-roll CNC slicer is a professional slicer for frozen lamb and frozen beef. The whole machine is made of food-grade 304 stainless steel, and the working platform is made of food-specific organic materials. The CNC system and distribution box are completely waterproof, flame-retardant, and stainless steel knives. Durable and anti-rust, the whole machine can be directly rinsed and disinfected with high-pressure water gun. The high-end CNC beef and mutton slicer has all the functions of an ordinary CNC slicer, and on this basis, an automatic pressing function is added to realize automatic pressing. It is easy to clean, safe and hygienic, and save labor.

The working principle of the eight-volume CNC slicer:

The working principle of the CNC 8-roll automatic slicer is relatively simple, that is, by using the sharp cutting surface of the slicer, the frozen meat is sliced into slices according to the ratio or width of one point. It is suitable for hotels, restaurants, canteens, meat processing plants and other units. Frozen meat slicer is also called mutton slicer and mutton slicer.

The performance advantages of the eight-volume CNC slicer:

The machine has compact structure, beautiful appearance, simple operation, high efficiency, low power consumption, easy cleaning and maintenance, safe and hygienic. It cuts raw meat into meat slices, etc. The meat cutting effect is uniform and can be automatically rolled into rolls. Imported Italian blades and belts are used. And with a unique automatic lubrication device and powerful power, it is an indispensable meat processing machine for hotels, restaurants, canteens, meat processing plants and other units. It is suitable for hot pot restaurants, restaurants, hotels and food processing plants, and the meat cutting effect is even. , Adopting dual-axis design, especially stable and durable!

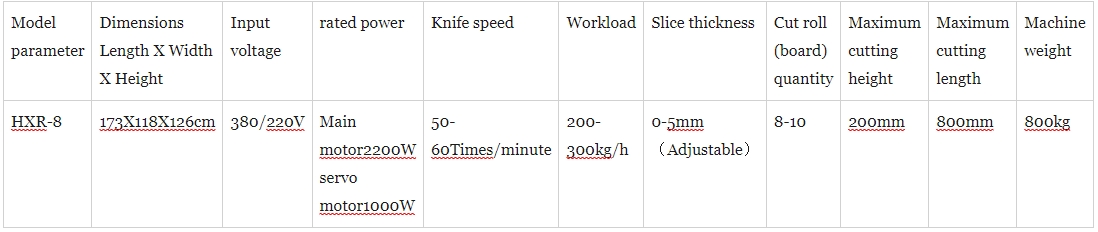

Parameter description of eight-volume CNC slicer:

Advantages of the 8-roll CNC slicer:

1. High working efficiency, 120 slices per minute can be sliced.

2. Install the dual-guide propulsion system and the split meat pressing system to ensure the uniformity of the slices.

3. The cut meat rolls can be sent out neatly, which is more convenient for packaging.

4. This machine is highly efficient, safe to operate, fully automatic operation, saving labor costs, and ensuring benefits.

5. The machine adopts a stainless steel case with good safety protection performance.

6. Infrared sensor safety protection can effectively protect the safety of operators.

7. It can cut out a variety of roll types such as thick rolls, thin rolls, long rolls, straight sheets, etc.

8. This machine is a machine that can cut fat beef slabs upright in the straight cutting machine industry.

9. Both the front and rear workbenches are equipped with PVC food-specific polymer heat insulation boards to effectively prevent the meat rolls from melting during cutting.

Precautions for the use of the eight-volume CNC slicer:

1. When the mutton slicer is in use, the meat must be frozen and hardened moderately, generally above “-6°C”, and should not be over-frozen. If the meat is too hard, it should be thawed first. The meat must not contain bones to avoid damage to the mutton slices. Machine blade.

2. If you feel that the mutton slicer is unstable during use, there are screw holes on the machine that can be fixed on the table for better use.

3. For frozen meat rolls, use the lamb slicer with the skin facing inwards. The fresh meat is facing outwards, one is good-looking, and the other is good to cut without a knife.

4. If the knife slips and the meat cannot be gripped after cutting several hundred catties continuously, it means that the blade of the lamb slicer has stopped, and the knife should be sharpened.

5. When the mutton slicer is moving, you can’t move it to the left (the direction of the meat). This will deform the knife. This is the most important point.